Consumers now have more buying power than ever before. Companies can no longer depend on loyalty if the fulfillment experience doesn’t stack up against the competition. Ensuring you maintain an efficient flow of products and goods across the entire supply chain depends on adopting the latest technologies and systems that optimize your operations.

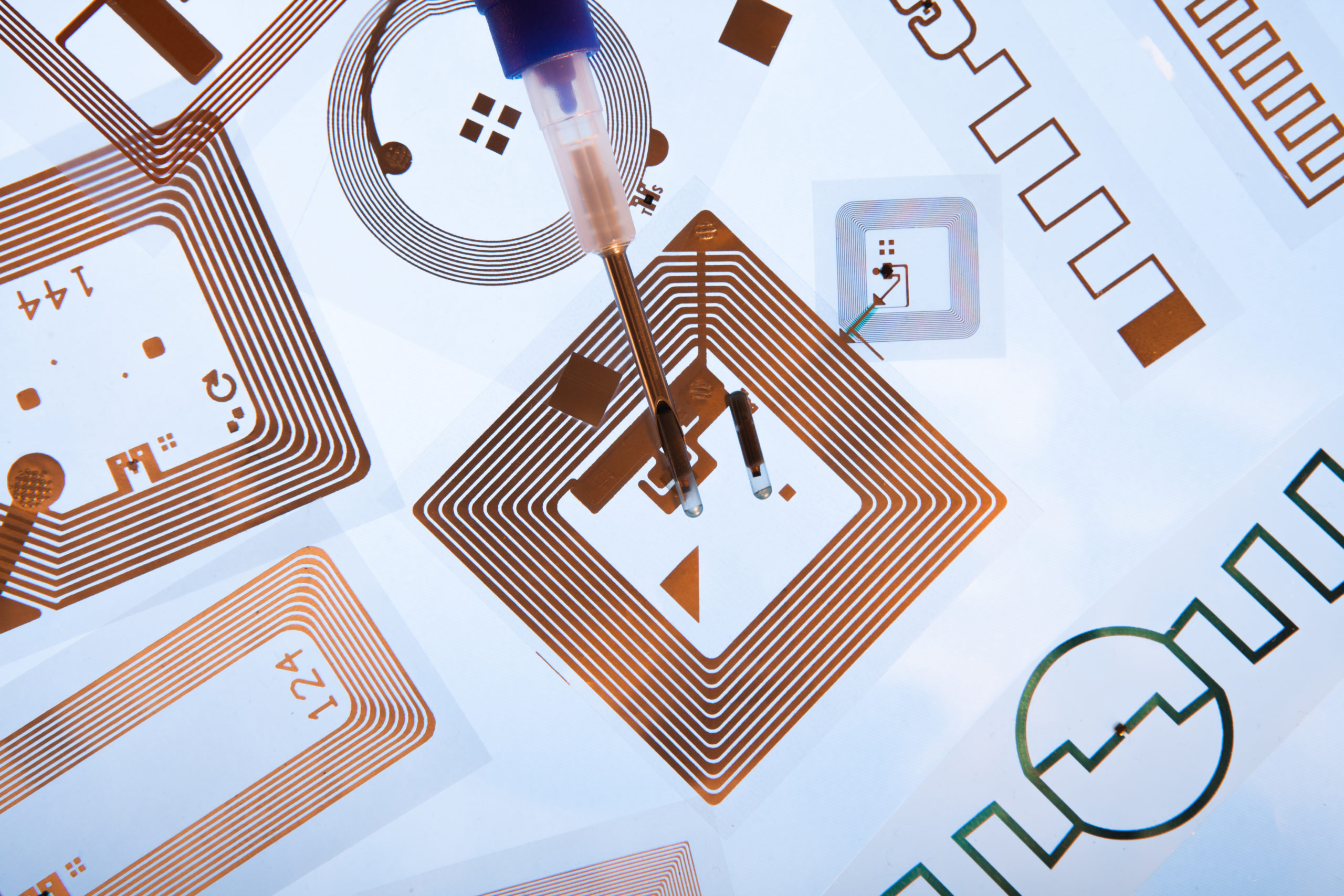

RFID has the potential to reshape all your processes, adding new efficiencies and giving you greater insight into where bottlenecks lie. Amazon Go recently opened a completely cashier-less store, proving that it’s possible to enhance customer experience using RFID technology.

With a variety of optimization solutions available, here’s how to achieve better stock placement with RFID for your warehouse operations and fulfillment processes.

Quick Takeaways:

- Integrated processes using RFID throughout supply and value chains allows for greater visibility and improved planning

- RFID supports any of the replenishment models deployed in your warehouses and retail locations with minimal effort

- The technology provides seamless experiences for your customers and reduces the burden on staff who have strict deadlines for order fulfillment

5 Ways to Achieve Better Stock Placement with RFID

Stock and inventory replenishment is probably one of the most important disciplines in your business. Efficiently moving your goods from reserve storage to distribution centers and then to the shelves of a retail location or a fulfillment center isn’t easy. Any snag in the process can delay deliveries, or even worse, lead to a stock-out situation. Supply chains saw a major increase in disruption last year due to COVID-19.

It’s for this reason that most organizations now use some form of intelligent RFID tags to alert warehouse staff or automatically reorder products as required. Consider these five ways that RFID can improve your replenishment and placement operations.

1. Access to Detailed Information Enables Better Planning

Ideally, you’ll want to avoid overstocking to save on storage space while also ensuring on-time delivery to meet the necessary demand. Planning your replenishment cycles using accurate RFID data enables you to maintain enough buffer stock levels and helps you identify which poorly-selling products are taking up valuable real estate. You can also track vendor and supplier performance, indicating deficiencies within their internal processes.

2. Automated Replenishment for High-Throughput Items

If needed, you can automate most of your replenishment tasks by triggering a restock once a customer makes a purchase. The RFID tag retains all the required product information to start the upstream processes. It may be that you run different replenishment models for some types of SKUs.

With RFID technology, you can trigger a demand inventory replenishment for some goods and a top-off or min/max process for others. You have the necessary flexibility to come up with a unique solution for your company.

3. Complete Tracking of Product to the End-User

Increasing the transparency of the fulfillment process will reduce losses and keep customers happy. Tracking the RFID of the product from your supplier, warehouse, and the retail store or the buyer’s location allows you to respond effectively in case of emergency. In certain cases, you could implement drop shipping for some of your products to help save money and storage space without damaging your reputation.

4. Process Optimization with Actionable Insights

Using historical data to map out the flow of products through all your locations can give you valuable insights and highlight other optimization opportunities. This information allows you to test different scenarios and establish where you are performing well, while determining which practices are costing you time and money. With granular data from all your stock placement and replenishment processes, you can refine every step of your operations.

5. Improving Facility Layout with Movement Tracking

Lastly, active wireless RFID enables you to track your people and goods (including customers) as they move through the facility. If you see where you can improve traffic flow in certain areas, you can modify your layout to improve efficiency. Strategically placing hands-free RIFD scanners will highlight any issues in your process.

Connect the Physical Product with Enterprise Resource Planning

Managing your inventory by connecting the actual goods with your entire ERP system can improve accuracy and planning. Radiofrequency identification doesn’t require you to scan individual products (like with barcodes), generating new information as workers move products around in your facility.

RFID Integration with Stock Placement and Replenishment Systems

Every element of your operation can benefit from integrated RFID solutions. In retail settings, you can use automated replenishment, cashier-less checkouts, and triggering upstream processes based on specific events to reduce the burden on staff and vendors.

RFID technologies allow for a detailed overview of all your retail and product value chains. It provides you with the ability to track all activities, forecast demand accurately, and manage stock levels proactively.

Another benefit of using RFID replenishment systems is optimizing your lot-sizing methods. Whether you use fixed or economic order quantity (FOQ or EOQ), lot-for-lot (LFL), or periods of supply (POS) processes, RFID ensures you eliminate costly mistakes and streamline all your organization’s processes.

Find Out More About Achieving Better Stock Placement with RFID at RFID Journal LIVE!

RFID Journal LIVE! is a platform that helps businesses using insights that drive growth and operational efficiency. With modern technology, system integration, and digital transformation that scales effortlessly with your business, RFID Journal LIVE! are your partners for future success.

We serve the retail, security, safety, and technology sectors, creating opportunities to collaborate and discover new trends in today’s business world. With our services and consultations grounded in the actionable data, your company can benefit from attending our range of events connecting more than 1.9 million consumers.

If your company wants to see how RFID can transform your entire value chain, sign up for our live events today.